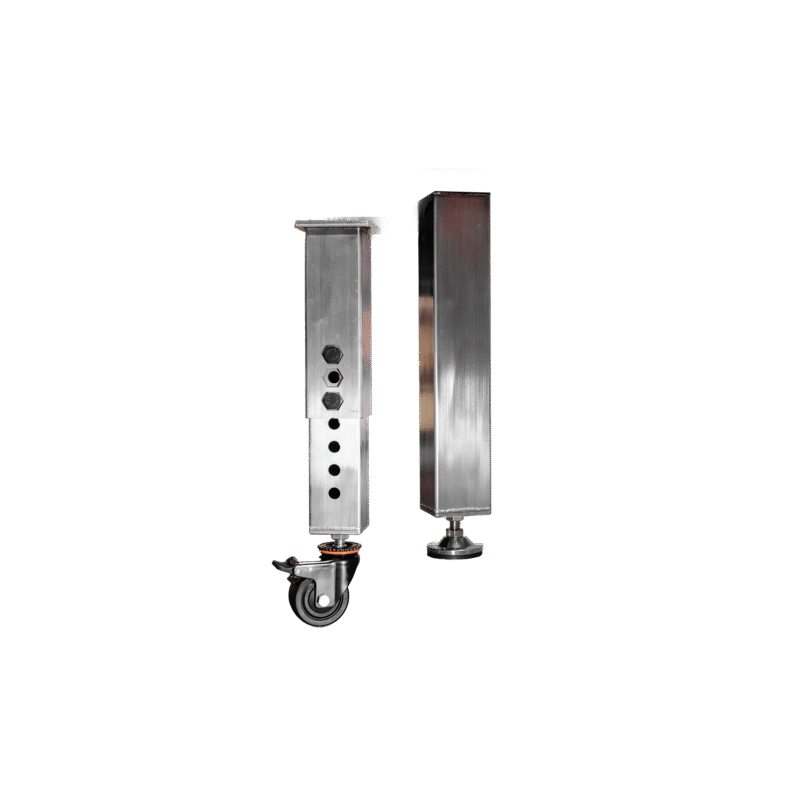

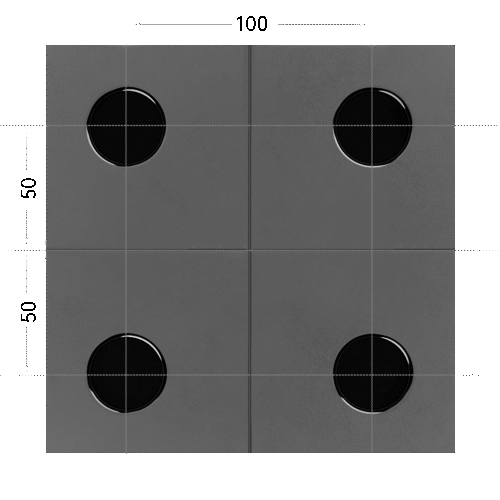

Standard hole diameter: 28mm(System 28).

Custom 16mm System available upon request

Our Special Offers

-

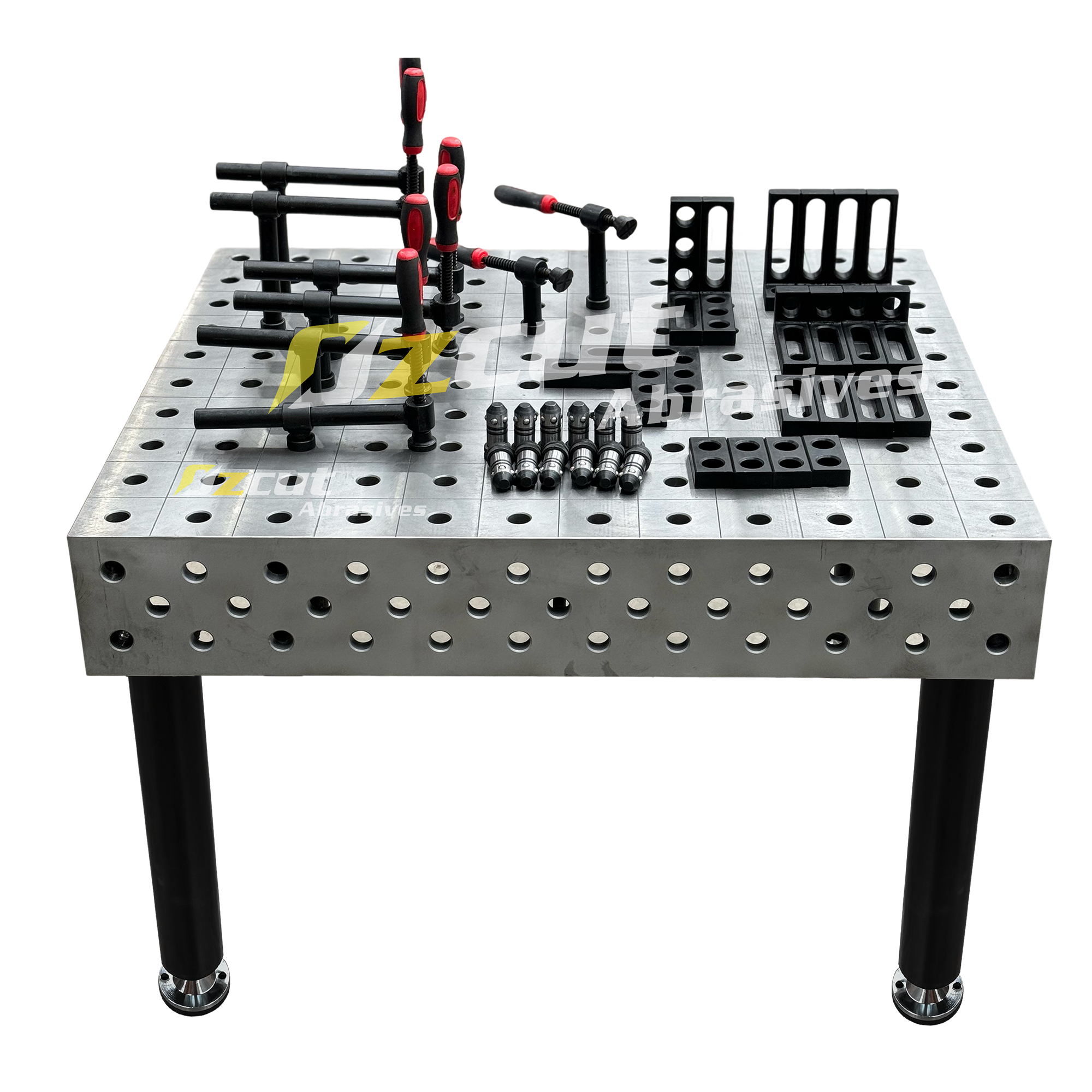

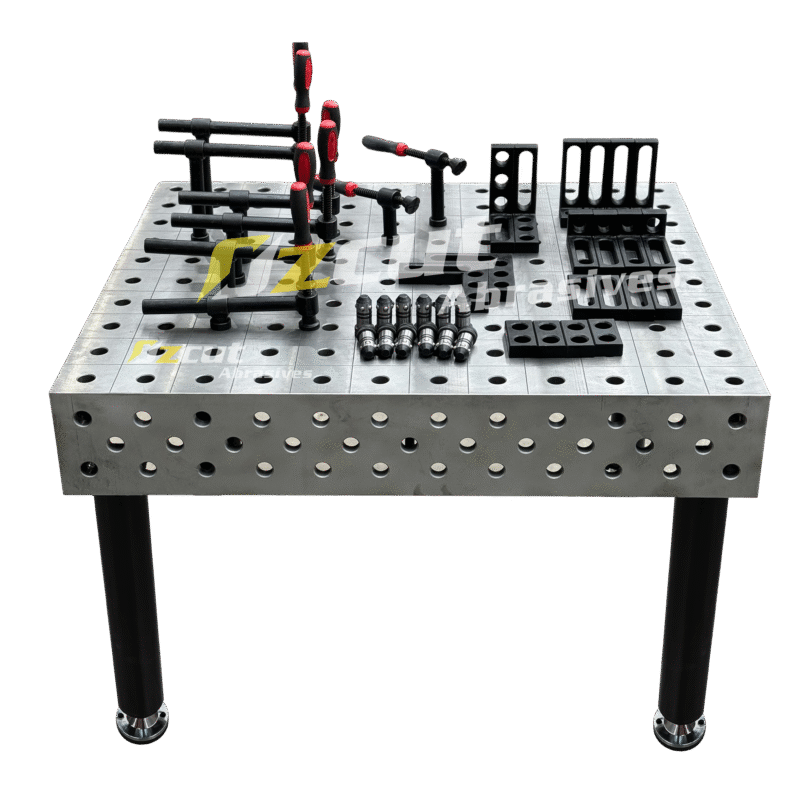

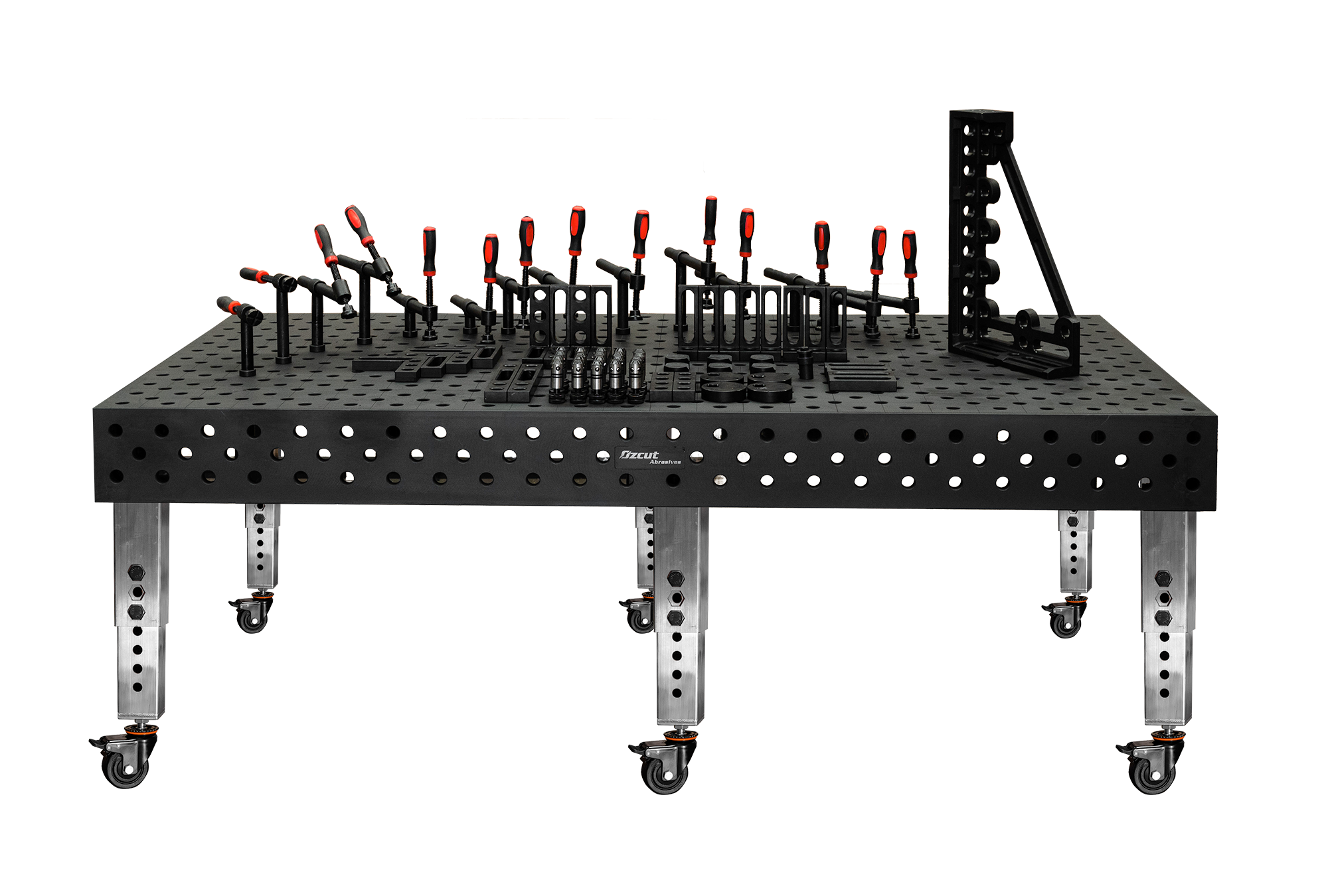

1000x1200mm Essentials Series Small Package | 42pc Small Toolkit

$2,380.00 inc. GST

1000x1200mm Essentials Series Small Package | 42pc Small Toolkit

$2,380.00 inc. GST

-

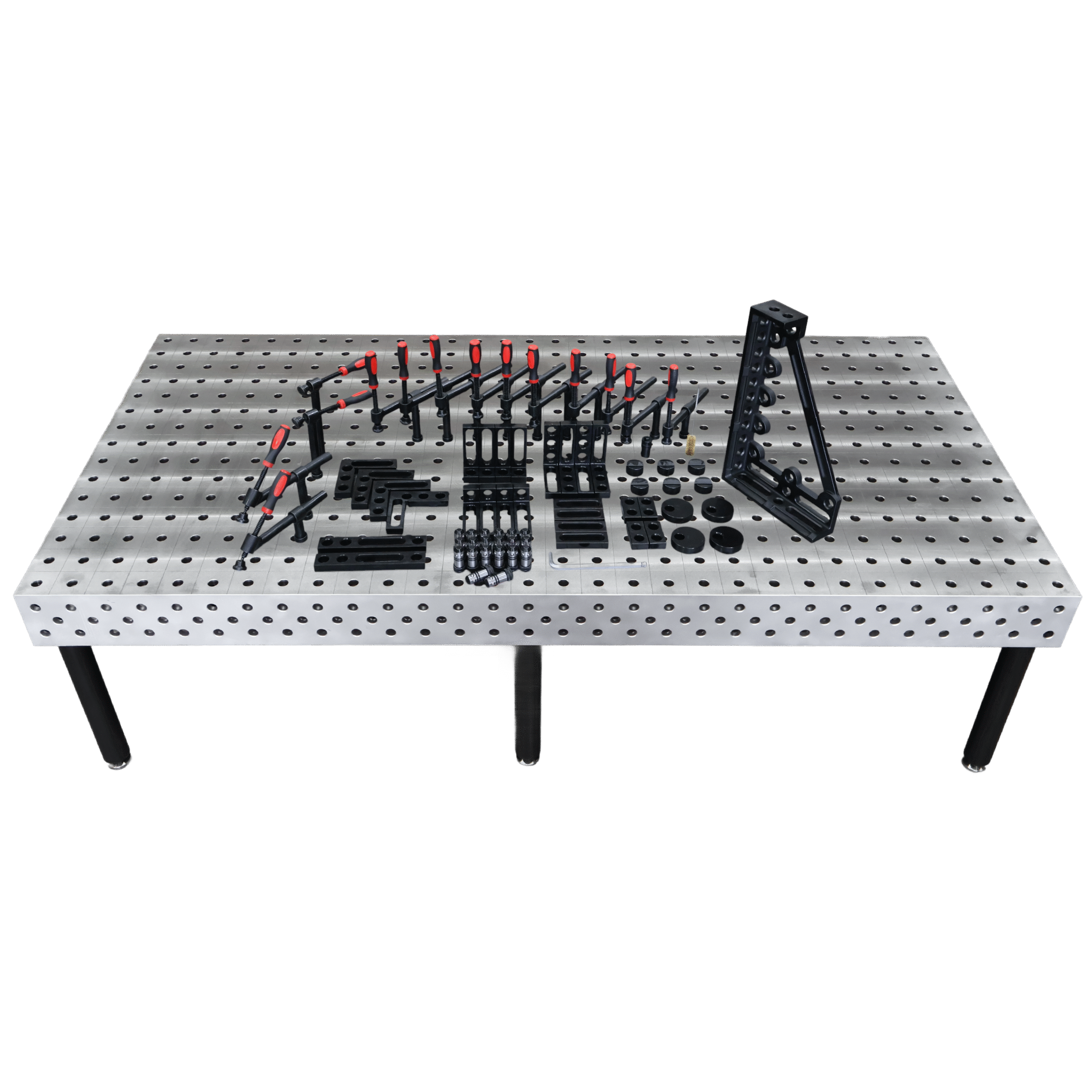

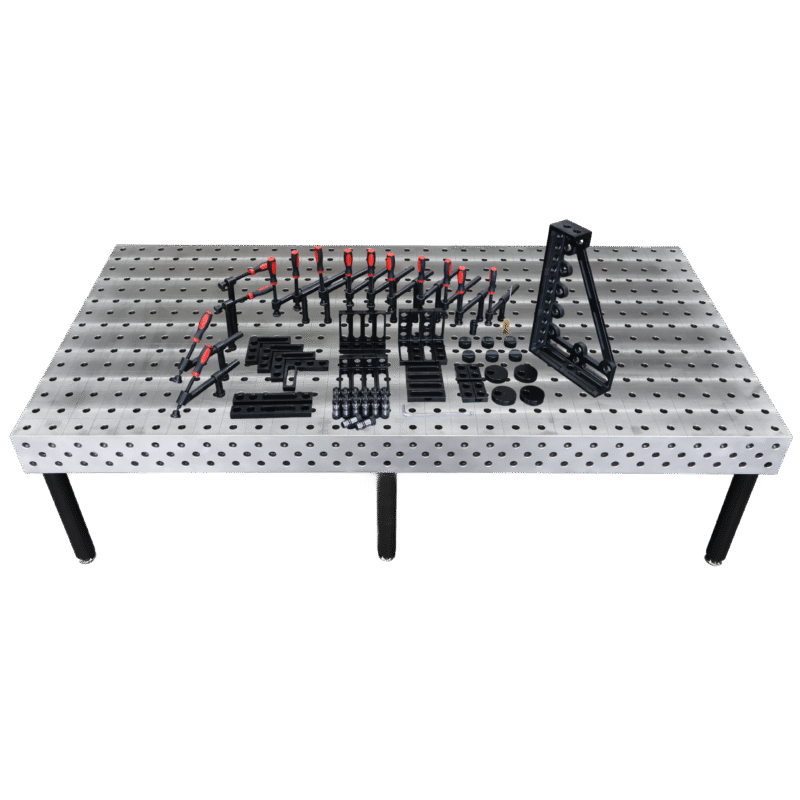

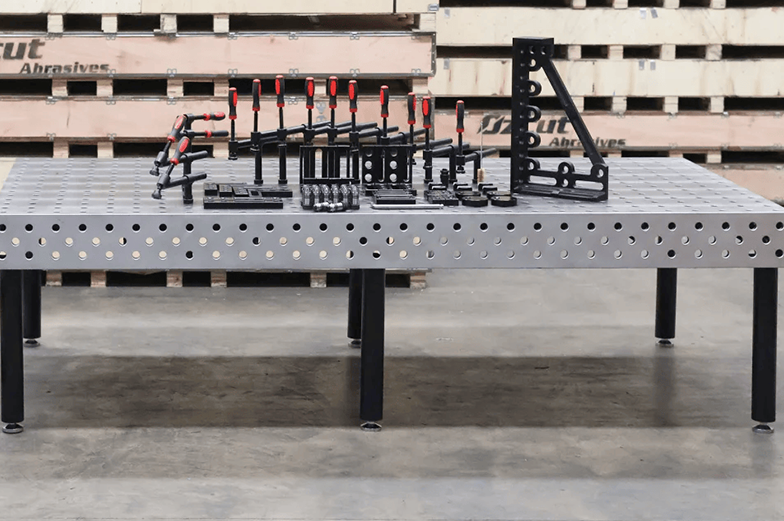

1500x3000mm Essentials Series Large Package | 74pc Large Toolkit

1500x3000mm Essentials Series Large Package | 74pc Large Toolkit

$5,780.00Original price was: $5,780.00.$5,679.00Current price is: $5,679.00. inc. GST -

1200x2400mm Pro Series Nitrided Cast Iron Package | 74pc Large Toolkit

$7,498.00 inc. GST

1200x2400mm Pro Series Nitrided Cast Iron Package | 74pc Large Toolkit

$7,498.00 inc. GST

-

1000x2000mm Pro Series Nitrided Steel Package | 42pc Small Toolkit

$5,451.00 inc. GST

1000x2000mm Pro Series Nitrided Steel Package | 42pc Small Toolkit

$5,451.00 inc. GST

Nitrided Steel

Nitrided Steel

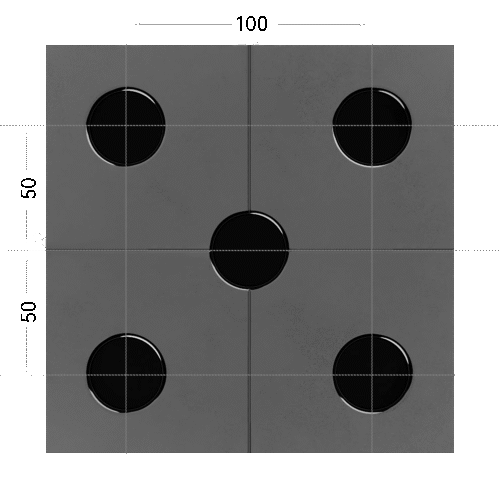

Standard Hole

Standard Hole

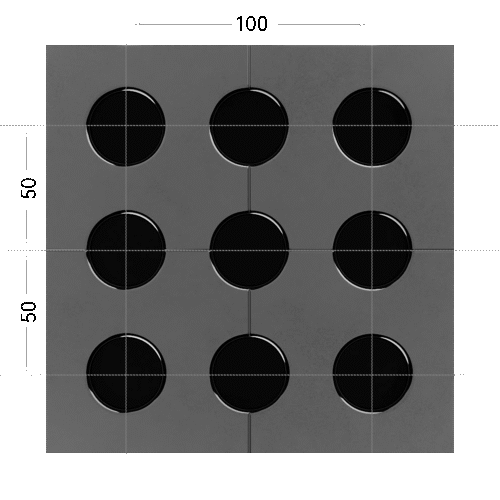

Diagonal Hole

Diagonal Hole

50x50mm

50x50mm

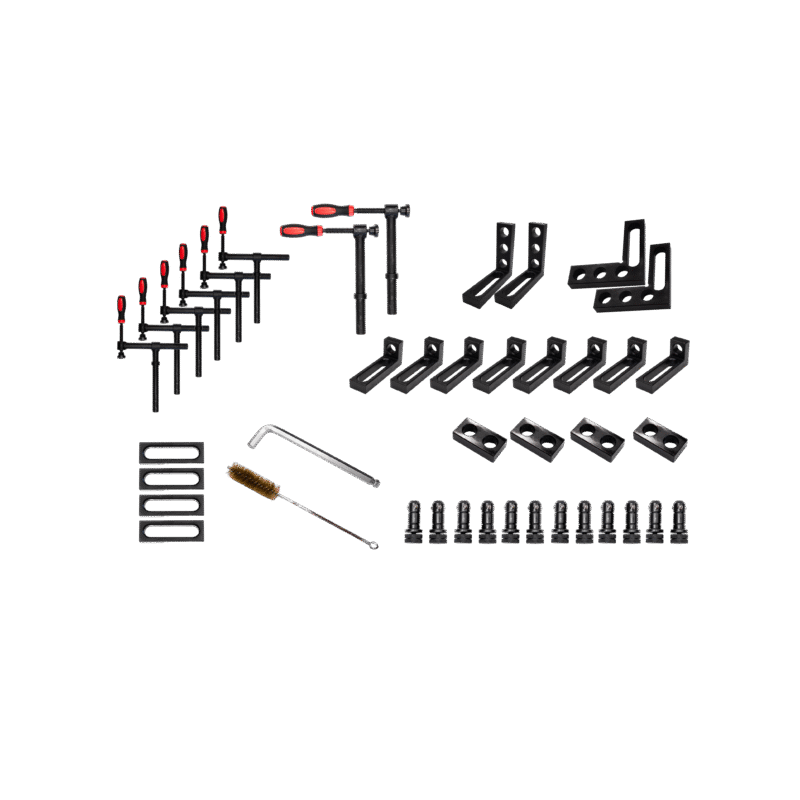

8x Small Locating Squares A28-32

8x Small Locating Squares A28-32

2x Medium Locating Squares A28-35

2x Medium Locating Squares A28-35

4x Extra Small Universal Stops A28-39

4x Extra Small Universal Stops A28-39

4x Small Universal Stop A28-40

4x Small Universal Stop A28-40

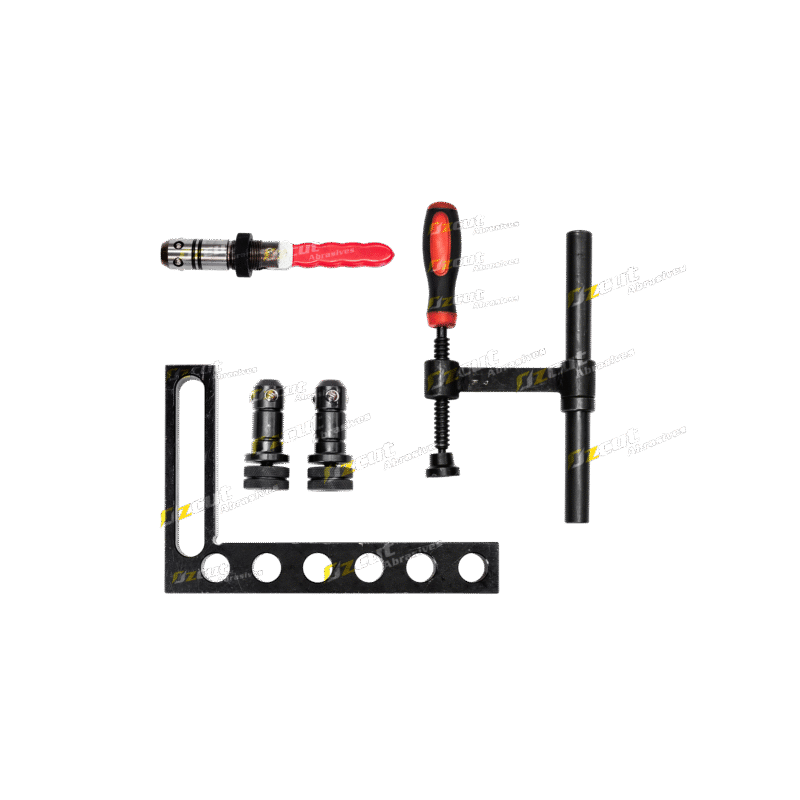

2x Small Flat Square A28-46

2x Small Flat Square A28-46

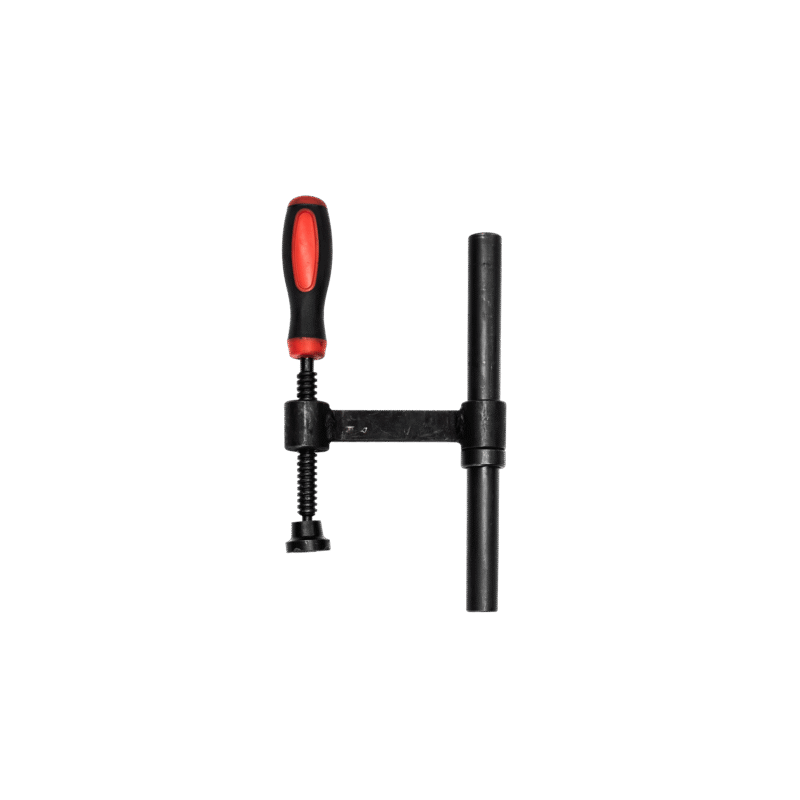

6x 180°Clamps A28-67

6x 180°Clamps A28-67

2x 90°Clamps A28-68

2x 90°Clamps A28-68

6x Standard Ball Lock Pins A28-79

6x Standard Ball Lock Pins A28-79

6x Adjustable Ball Lock Pins A28-79-ADJ

6x Adjustable Ball Lock Pins A28-79-ADJ

1x Hex Key A28-94

1x Hex Key A28-94

1x Brush A28-95

1x Brush A28-95

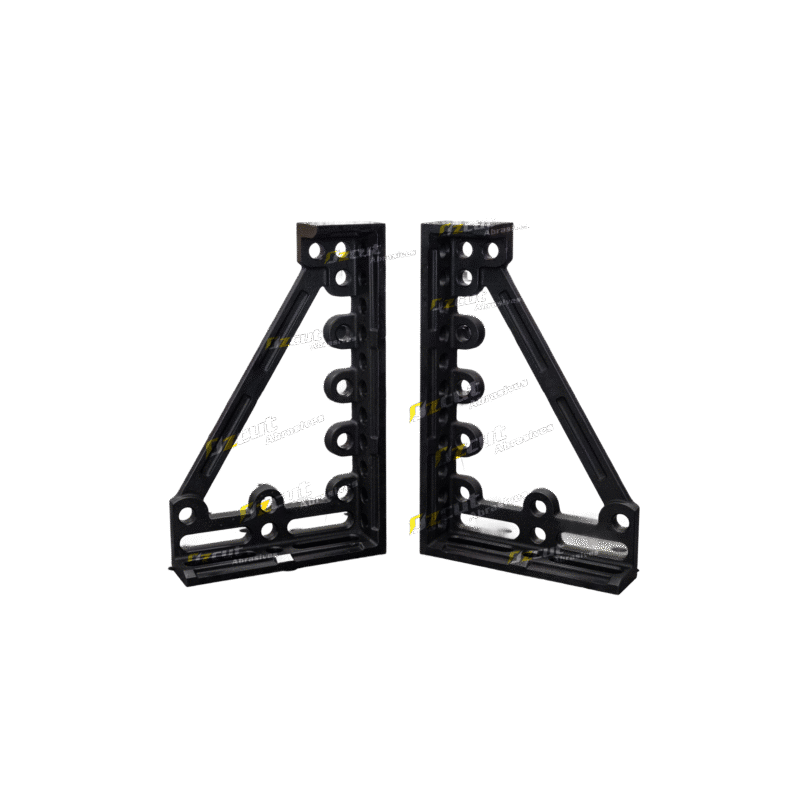

1x 600mm Cast iron Square A28-17

1x 600mm Cast iron Square A28-17

2x Large Universal Stops A28-42

2x Large Universal Stops A28-42

6x 58mm V Blocks A28-59

6x 58mm V Blocks A28-59

4x 75mm Locating Discs A28-65

4x 75mm Locating Discs A28-65

2x 45°Clamps A28-69

2x 45°Clamps A28-69

1x Earth Connector A28-91

1x Earth Connector A28-91